Brass Heat Set Inserts

10.0 INR/Piece

Product Details:

- Usage For Fitting Use

- Product Type Threaded Insert

- Material brass

- Application Plastic Molding

- Connection Female

- Shape Round

- Click to view more

X

Brass Heat Set Inserts Price And Quantity

- 2000 Piece

- 10.0 INR/Piece

- 60.00 - 250.00 INR/Piece

Brass Heat Set Inserts Product Specifications

- Round

- Female

- Plastic Molding

- brass

- Threaded Insert

- For Fitting Use

Brass Heat Set Inserts Trade Information

- Mumbai

- 2000 Piece Per Week

- 10 Days

- No

- Sample costs shipping and taxes has to be paid by the buyer

- Carton Box

- South America, Eastern Europe, Asia, Australia, Central America, North America, Western Europe, Middle East, Africa

- All India

Product Description

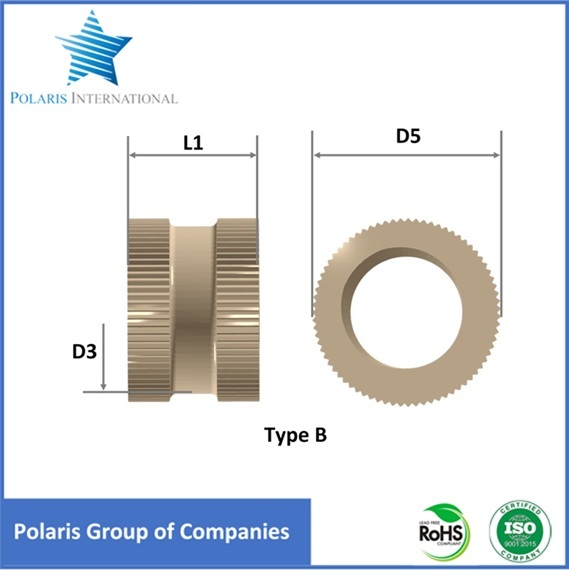

Type/Application

- Knurling:

- Brass Knurled Inserts

- Brass Straight Knurling Inserts

- Brass Diamond Knurling Inserts

- Brass Unidirectional Inserts

- Brass Cross Knurling Inserts

- Installation Method:

- Heat Set Inserts

- Ultrasonic Inserts

- Press-fit Inserts

- Molded-in Inserts

- Self-tapping Inserts

- Shape:

- Brass Round Inserts

- Brass Hex Inserts

- Brass Square Inserts

- Brass Collar Inserts

Industry/Application

- Brass Inserts for Electronics

- Brass Inserts for Automotive

- Brass Inserts for Telecommunication

- Brass Inserts for Electrical Components

- Brass Inserts for Sanitary Fittings

- Brass Inserts for Medical Equipment

- Brass Inserts for Home Appliances

- Brass Inserts for Furniture

Specification/Feature

- Material Grade:

- Free Cutting Brass Inserts (e.g., IS 319, CuZn39Pb3, BS 249)

- Thread Type:

- Metric Thread Brass Inserts (e.g., M2, M3, M4, M5, M6, M8, M10)

- ISO Metric Brass Inserts

- UNC/UNF Thread Brass Inserts

- BSW/BSP/BA Thread Brass Inserts

- Finish:

- Natural Finish Brass Inserts

- Nickel Plated Brass Inserts

- Tin Plated Brass Inserts

- Compliance:

- RoHS Compliant Brass Inserts

- REACH Compliant Brass Inserts

- ISO Certified Brass Inserts

Reliable Fitting Solutions for Plastic Molding

Our brass heat set inserts are specifically crafted to provide robust and lasting connections in plastic components. Suited for various industries, these inserts guarantee a secure hold while facilitating repair and reassembly. Their round design ensures seamless integration during plastic molding, helping manufacturers optimize production and maintain quality standards.

Why Choose Brass for Heat Set Inserts?

Brass is inherently known for its corrosion resistance, thermal conductivity, and machinability, making it the preferred choice for heat set inserts. Using brass extends the lifespan of the assembly, prevents rust, and enables repeated installation while maintaining thread integrity. Our inserts are engineered for easy integration into thermoplastics, aiding efficient production cycles.

FAQs of Brass Heat Set Inserts:

Q: How are brass heat set inserts used in plastic molding applications?

A: Brass heat set inserts are embedded into plastic components by heating, creating a threaded female connection. This offers a strong, stable hold for screws and allows plastic parts to be assembled and disassembled without damaging the threads.Q: What benefits do brass heat set inserts offer compared to other materials?

A: Brass provides excellent corrosion resistance, thermal stability, and consistent threading. These properties mean the inserts resist rust, maintain structural integrity over time, and support repeated screw insertion and removal, making them ideal for high-quality assembly work.Q: When should I use heat set inserts in my manufacturing process?

A: You should incorporate brass heat set inserts during or after the plastic molding process, typically wherever secure, long-lasting threaded connections are required in plastic parts, such as electronics housings, automotive components, or consumer goods.Q: Where can these brass heat set inserts be sourced from?

A: We are an established exporter, manufacturer, and supplier based in India, offering these inserts to domestic and international clients. Orders can be placed directly through our sales team or online platforms.Q: What is the process for installing brass heat set inserts in plastic?

A: The process involves heating the insert, then pressing it into the pre-molded hole in a plastic part. As the insert heats, it slightly melts the surrounding plastic, creating a secure bond when cooled. This ensures a tight fit and durable thread formation.Q: How can manufacturers benefit from using brass heat set inserts?

A: These inserts improve the longevity of plastic assemblies, prevent stripping of threads, and make maintenance or repair easier by allowing repeated disassembly and reassembly. They also raise the overall quality and reliability of the finished products.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send SMS

Send SMS

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese