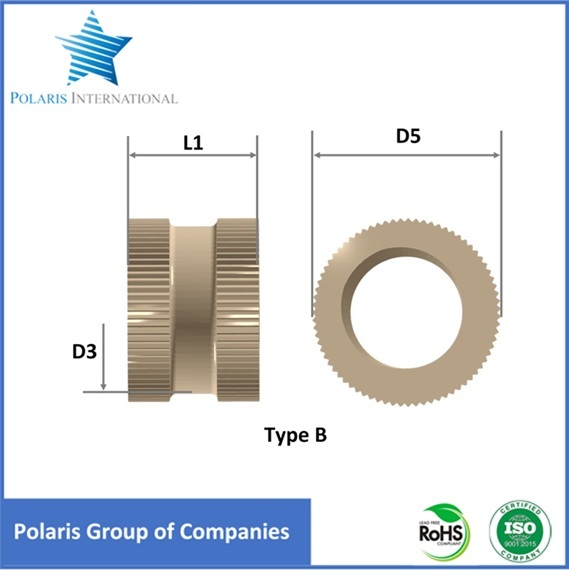

brass threaded moulding inserts

5 INR/Piece

Product Details:

- Finish Nickel Plated

- Application Electronics

- Product Type Brass Threaded Insert

- Processing Type Turning

- Size M2, M3, M4, M5, M6, M8, M10

- Color yellow

- Surface Finishing Nickel Plated

- Click to view more

X

brass threaded moulding inserts Price And Quantity

- 5 INR/Piece

- 5000 Piece

brass threaded moulding inserts Product Specifications

- Nickel Plated

- M2, M3, M4, M5, M6, M8, M10

- yellow

- brass

- Plastic Moulding

- 0.05 Millimeter (mm)

- Yes

- Female

- Nickel Plated

- Electronics

- Turning

- Round

- Brass Threaded Insert

brass threaded moulding inserts Trade Information

- JNPT India

- Paypal, Cash Against Delivery (CAD), Cash in Advance (CID), Telegraphic Transfer (T/T)

- 100000 Piece Per Month

- 30 Days

- Yes

- Sample costs shipping and taxes has to be paid by the buyer

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Maharashtra

- ISO 9001:2015

Product Description

Type/Application

- Knurling:

- Brass Knurled Inserts

- Brass Straight Knurling Inserts

- Brass Diamond Knurling Inserts

- Brass Unidirectional Inserts

- Brass Cross Knurling Inserts

- Installation Method:

- Heat Set Inserts

- Ultrasonic Inserts

- Press-fit Inserts

- Molded-in Inserts

- Self-tapping Inserts

- Shape:

- Brass Round Inserts

- Brass Hex Inserts

- Brass Square Inserts

- Brass Collar Inserts

Industry/Application

- Brass Inserts for Electronics

- Brass Inserts for Automotive

- Brass Inserts for Telecommunication

- Brass Inserts for Electrical Components

- Brass Inserts for Sanitary Fittings

- Brass Inserts for Medical Equipment

- Brass Inserts for Home Appliances

- Brass Inserts for Furniture

Specification/Feature

- Material Grade:

- Free Cutting Brass Inserts (e.g., IS 319, CuZn39Pb3, BS 249)

- Thread Type:

- Metric Thread Brass Inserts (e.g., M2, M3, M4, M5, M6, M8, M10)

- ISO Metric Brass Inserts

- UNC/UNF Thread Brass Inserts

- BSW/BSP/BA Thread Brass Inserts

- Finish:

- Natural Finish Brass Inserts

- Nickel Plated Brass Inserts

- Tin Plated Brass Inserts

- Compliance:

- RoHS Compliant Brass Inserts

- REACH Compliant Brass Inserts

- ISO Certified Brass Inserts

Precision Engineering with CNC Turning

Our brass threaded moulding inserts are produced using advanced CNC turning machines, ensuring exceptional dimensional accuracy and a consistent, smooth surface. This precise manufacturing process guarantees a snug fit, superior thread quality, and extended component life for demanding electronic and plastic moulding applications.

Corrosion Resistance with Nickel Plating

Each insert is nickel-plated to create a strong protective barrier against corrosion, oxidation, and wear. The nickel finish not only enhances durability but also maintains the aesthetic appeal of the inserts, making them ideal for electronics and environments requiring long-lasting performance.

FAQs of brass threaded moulding inserts:

Q: How are brass threaded moulding inserts installed in plastic moulding applications?

A: Brass threaded moulding inserts are typically embedded into plastic components through press-in or heat staking methods. Their precise round shape and tolerance facilitate secure and stable installation within plastic housings used in electronics.Q: What advantages does CNC machining provide for these inserts?

A: CNC machining ensures each brass insert is produced with outstanding precision, providing consistent thread profiles and maintaining tight tolerances of up to 0.05 mm. This enhances assembly reliability and supports high-performance requirements in electronic components.Q: When is nickel-plating especially beneficial for brass inserts?

A: Nickel plating is particularly beneficial in environments where corrosion resistance and enhanced durability are critical, such as electronics manufacturing. It also contributes to steady electrical conductivity and a premium finish.Q: Where can these brass moulding inserts be effectively utilized?

A: These inserts are ideal for use in the electronics industry, especially where threaded connections are needed in plastic components, circuit boards, and enclosures requiring robust, corrosion-resistant fastening solutions.Q: What is the processing type used for manufacturing these inserts?

A: The inserts are manufactured using a turning process on CNC machines, which provides exceptional precision and repeatability compared to traditional manual methods.Q: How does the round shape of the insert improve its usage in moulding?

A: The round design allows easy insertion and uniform distribution of stresses, reducing the risk of cracking or distortion in plastic materials during installation and use, especially in electronics assemblies.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send SMS

Send SMS

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese